6015

The Cat® 6015 Hydraulic Shovel lets you move more material at a lower cost, so you can achieve production targets, deliver on your commitments, meet deadlines and maximize your profitability. With class-leading tool carrying capacity, increased durability and the most powerful engine in its class, the Cat 6015 generates higher productivity and fuel efficiency than other shovels. And it’s offered with more and better options that let you match your machine to your operation — from access and cold weather packages to multiple stick and track pad options. In addition, a large range of buckets is available, giving you optimum payload and machine efficiency for your operation. And the 6015’s high tool carrying capacity gives you the ability to employ large buckets and move more in fewer cycles.

SAFETY

- Operator Protective Guard (Top Guard) certified cab plus optional front guard.

- Excellent visibility with unobstructed view of digging environment and upward view through skylight, plus optional two-camera system to reduce blind spots and enhance situational awareness.

- Safer access and egress with anti-slip walkways and optional powered 45-degree access stairway.

- Five emergency shut-off switches, with one easily accessible in the cab to shut down the electrical system in case of emergency.

- Safer service with lockable starter and battery isolation switch cabinet.

OPERATOR CAB

- Heated, pneumatically-cushioned and fully adjustable suspension seat that provides height and weight adjustments, lumbar support, wide arm/wrist rests and a wide retractable seat belt for full operator comfort and support.

- Maintained internal ambient temperature with air conditioning, heat and defroster, and improved filtration with fresh air filter that removes dust and particles, plus a second internal filter that cleans recirculated air inside the cab.

- Easily accessible ergonomic joysticks with Electronic-Hydraulic Servo Control, which delivers dynamic and precise response and ensures no hydraulic lines are present in the cab.

- Large, 7 in (178 mm) color touchscreen for convenient troubleshooting and service assistance.

- Independently adjustable joystick consoles, plus joystick controls that allow pattern to be changed for enhanced safety and improved operator experience.

RELIABILITY & DURABILITY

- Rugged Cat heavy duty undercarriage designed to increase uptime, deliver longer service life and withstand increased tramming over rough mine site terrain, with features such as grease lubrication, GLT4 sealing technology and oil-filled rolling components that help it last at least 2,000 hours longer than dry track designs.

- Cat exclusive Positive Pin Retention 2 (PPR2) track design, which mechanically locks the link to the pin to resist pin walking and link cracking to deliver reliable sealing and maximum track life.

- Heavy duty fixed-axle rollers and idlers for improved performance, increased wear life, reduced internal friction and overheating, and elimination of grease consumption and lines.

- Heavy duty track group, which handles high field loads, and reduced pitch extension wear, which increases track chain life by 20% to 40%.

- Structures designed and fabricated to withstand the toughest digging conditions, with high-strength steel; full penetration, profiled and ground welds at critical junctures; and booms and sticks that are stress-relieved after welding.

- Efficient Independent Oil Cooling system, which protects and extends the life of hydraulic components.

PRODUCTIVITY & PERFORMANCE

- Faster cycle times and increased productivity thanks to Cat C27 engine, which is the most powerful in its class and provides top performance over an exceptional service life.

- Fast cycle times and improved energy efficiency delivered by closed-loop swing system, which also generates less heat.

- Proportional Priority Pressure Compensating (PPPC) hydraulic system, which varies hydraulic oil flow for smooth, predictable operation and greater operator efficiency.

- Load Enhanced Anticipatory Control (LEAC), which ensures faster and more consistent engine regulation by preventing lug, which, in turn, reduces fuel consumption.

- Engine Torque Load Control (ETLC), which reduces hydraulic pump output based on available engine torque, desired engine speed, actual engine speed and estimated hydraulic load — providing power to the functions that need it to move material quickly and efficiently.

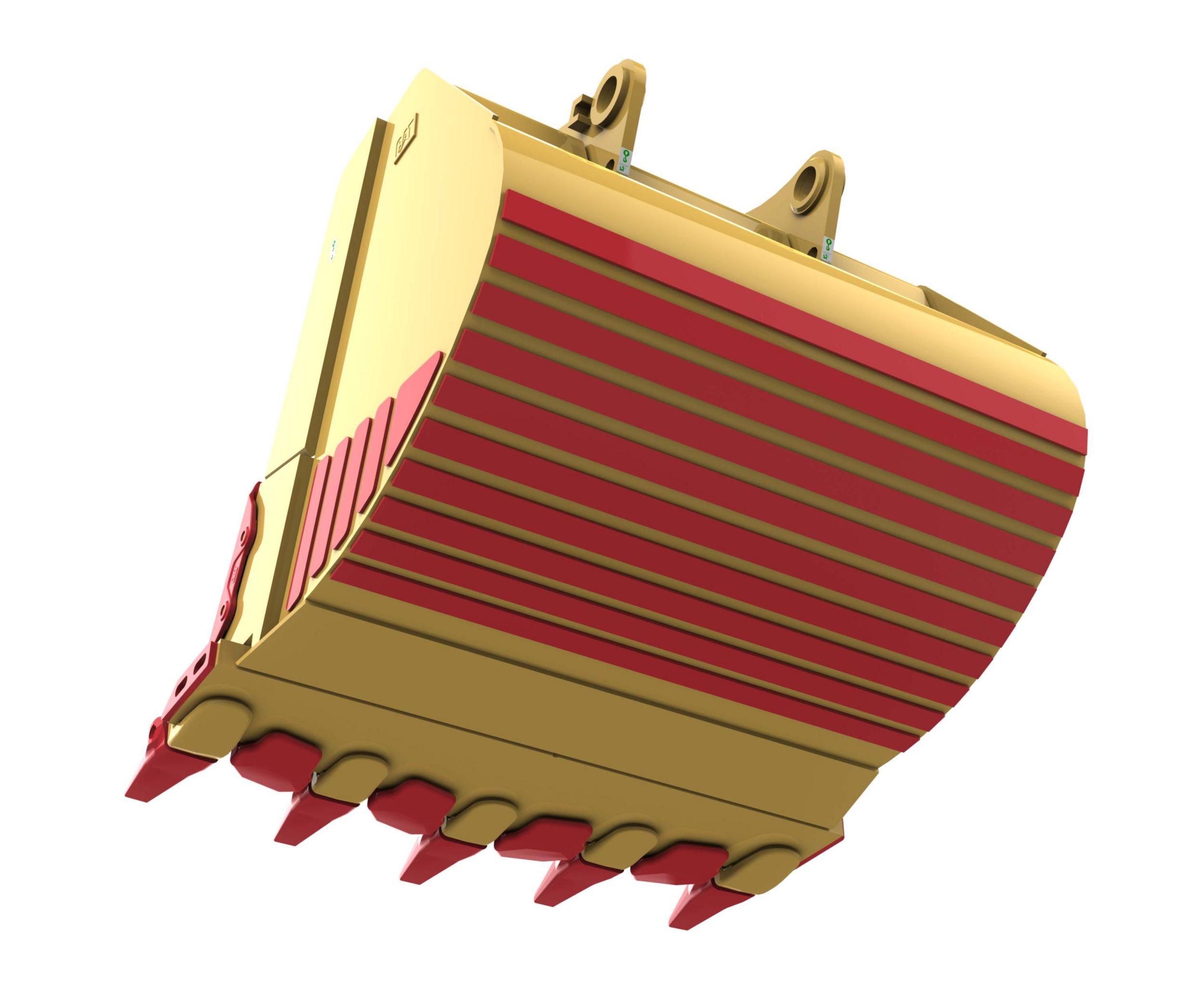

BUCKETS & GET

- Buckets and ground engaging tools (GET) designed to maximize durability and productivity, ideally matched to your shovel and application, and rebuildable, with wear components available as service parts.

- Integrated to work as part of a machine system — helping you achieve high productivity and the lowest cost per ton.

- Hammerless GET designed specifically for the 6015, with no special tools required for removal and installation.

- New standard rock bucket equipped with the new M75 GET, which is 20% stronger than the previous C70 GET and moves 8.1 m3 (10.6 yd3) of material, carrying up to 14.6 tonnes (16.1 tons).

- Wear packages that protect your investment, including special liner material and lip shrouds, wing shrouds and heel shrouds.

CONNECTIVITY & TECHNOLOGY

- Greater connectivity with improved Product Link™ Elite system, which increases the availability of data provided by the 6015 and allows it to collect and transmit information into locally hosted or cloud-hosted applications.

- Factory-ready for Cat MineStar™ Solutions, with a range of capabilities that meet the needs of your fleet.

- MineStar Health, which lets you collect and monitor machine data so you can be proactive and maximize uptime.

- MineStar Edge™, which makes it possible to measure, manage, analyze and optimize your entire operation.

- Designed for the future, with expandable electronic systems that allow smooth integration of MineStar or other electronic capabilities.

SERVICEABILITY

- Access to Cat Electronic Technician, which helps dealer service personnel more easily diagnose and prevent issues.

- Enhanced warning levels for hydraulic oil temperature and improved data link diagnostics for reduced downtime.

- Visual inspection ports for slew drive pinions and ring gear, commonization of charging ports and charging tool and new electronic pilot pressure monitoring via ET.

- Ground-level service station that provides easy access to fast-fill diesel fuel and grease connections.

- Maintenance-free Positive Pin Retention tracks that are specially machined to extend internal pin/bushing wear life and fatigue resistance.

SUSTAINABILITY

- Highly regulated C27 engine certified to meet U.S. EPA Tier 4 Final/EU Stage V emissions standards without the need for DEF — saving time and cost during maintenance.

- Reduce fuel consumption with Load Enhanced Anticipatory Control (LEAC) system.

- Sound-suppressed power module to keep spectator sound levels low.

- Preservation of raw materials, energy conservation and reduced emissions through the Cat Reman and Cat Rebuild programs, which return end-of-life components to like-new condition.