Training

William Adams Institute of Training

The William Adams Institute of Training offers industry specific learning programs utilising new and emerging technologies with access to a variety of machines, components, simulators and training aids that reinforce the learning experience.

Our learning resources have been developed through close consultation with industry and are continuously reviewed and updated to keep up with ever-changing technology and processes.

Learn from industry-leading experts who have mastered the art of success in their fields. Our instructors are passionate about your growth!

Gain practical skills you can immediately apply to your job. We’re all about turning knowledge into action!

We offer training to our customers in the following areas:

- Nationally Recognised Training

- Technical / Maintenance Training

- Online Learning Solutions

- Training consulting services

Click on our course catalogue and course calendar for more details or send us an email.

COURSE OUTLINE

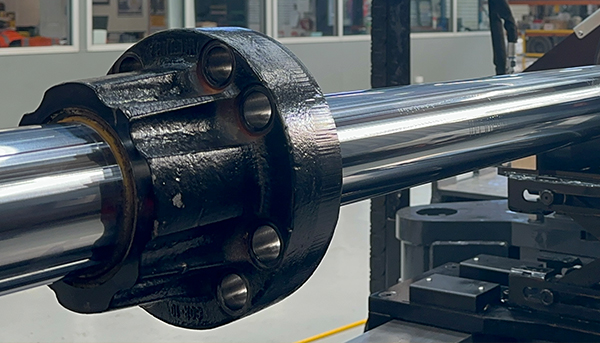

All courses include practical hands on elements with Caterpillar components, parts, or machines. All courses have a high focus on safe work and Contamination Control practices to maintain employee safety and equipment performance.

Preventative Maintenance (1 day)

Learn how to take a great oil sample, change filters, and complete basic inspection and maintenance activities on Caterpillar machinery.

TOPICS INCLUDE

- Performing adjustments required at interval servicing as well as fluid and filter changes

- Understanding lubrication requirements

- How to correct conduct scheduled oil sampling procedures

- Technical analysis walk-around inspections

- Using the MIS maintenance interval schedule

Electronic Technician (ET) (0.5 day)

View diagnostic codes and events and complete simple tests and calibrations using Caterpillar’s Electronic Technician software.

TOPICS INCLUDE

- Viewing active and logged diagnostic codes and parameters

- Viewing events where irregularities are logged on the ECM

- Graphing a group of status parameters

- Performing diagnostic tests and calibrations

- Creating product status reports.

Undercarriage Fundamentals (1 day)

Understand undercarriage components and how they work on Caterpillar machines. Test and adjust undercarriage on track type tractors, loaders, and excavators.

TOPICS INCLUDE

- What is meant by ‘low sprocket’ and ‘elevated sprocket’ systems

- Identifying undercarriage components and locations

- Testing and adjusting of undercarriages

- Safety when working with undercarriages

- Understanding how undercarriages work and wear

Electronic Engines

(2 days)

Learn to diagnose, service, and repair electronic fuel systems on common Caterpillar engines.

TOPICS INCLUDE

- Basic Diesel Engine principals

- Completing MEUI Engine Electronic Operation and Repairs

Completing HEUI Engine Electronic Operation and Repairs

Hydraulic Fundamentals

(1 day)

Confidently read hydraulic schematics and diagnose faults in simple hydraulic systems commonly found on Caterpillar machines.

TOPICS INCLUDE

- Understanding basic hydraulic principles and identifying components

- Identifying symbols on schematics

- Explaining the functional of various valves

- Troubleshooting techniques

- Understanding how engine performance affects hydraulic performance

Electrical Fundamentals

(1 day)

12v electrical basics including simple circuits, ohm’s law, using a digital multimeter to troubleshoot, and connectors commonly found in Caterpillar product

TOPICS INCLUDE

- Understanding the fundamentals of electricity

- Understanding the proper use of a digital multimeter (DMM)

- Understanding Ohm’s Law and its importance in troubleshooting electrical/electronic systems

- Series circuits, Parallel circuits, Series-Parallel (combination) circuits

- Understanding the basic circuit faults and how to troubleshoot them

- Identify types of connectors used on Caterpillar products and to demonstrate the ability to service those connectors

Common Rail Fuel Systems

(1 day)

Understand the components, operation, maintenance, testing, and adjustment procedures for C4.2/C6.4 and C4.4/C6.6 ACERT engines used in Caterpillar machines

Hose and Couplings

(3 days)

Identify hose assemblies and use tooling and equipment correctly to assemble and clean hoses for use on Caterpillar machines.

TOPICS INCLUDE

- Correctly identify hoses, couplings, assemblies, O-rings, split flange clamps, and adapters

- Correctly use reference materials, tooling, and measuring tools.

- Correctly clean a hose in accordance with Caterpillar’s contamination control guidelines

- Assemble a hose using 423-4362 hose press

Troubleshooting Fundamentals (2 days)

Learn simple troubleshooting processes to speed up machine fault identification and rectification. Use a variety of processes best suited to the problem at hand. Practice your new skills on Caterpillar equipment and machinery.

TOPICS INCLUDE

- What is troubleshooting?

- The importance of troubleshooting

- Troubleshooting techniques

- Troubleshooting tools

- Common sense to troubleshooting

Diagnosing Electrical Faults (1 days)

Complete diagnostic tests on Caterpillar systems to identify faults with switches, sensors, and solenoids, commonly found on Caterpillar equipment

TOPICS INCLUDE:

- Understanding the diagnostic process

- Explaining the systems operation

- What is meant by ‘pull up voltage’

- Types of switches, sensors, and solenoids

- How to carry out fault finding, using the diagnostic process

Intermediate Hydraulics

(3 days)

Understand the function of hydraulic components including different pumps, control valves, and the control systems managing their performance. Diagnose, test, and adjust hydraulic operation on Caterpillar machines and systems to maximise performance.

TOPICS INCLUDE

- Understanding hydraulic systems

- Working with hydraulic pumps

- Working with control valves

- Hydraulic schematics

- Testing & adjusting components

- These systems as they relate to machines

Tier IV Final (After Treatment) (5 days)

Complete hands on diagnostic troubleshooting on Tier IV engines (interim, EU Stage 4, EU Stage 5) to address common faults and issues found in Caterpillar engines. Includes aftertreatment, air systems, fuel systems, catalytic reduction, operator interface, NOx reduction, and diesel exhaust fluid.