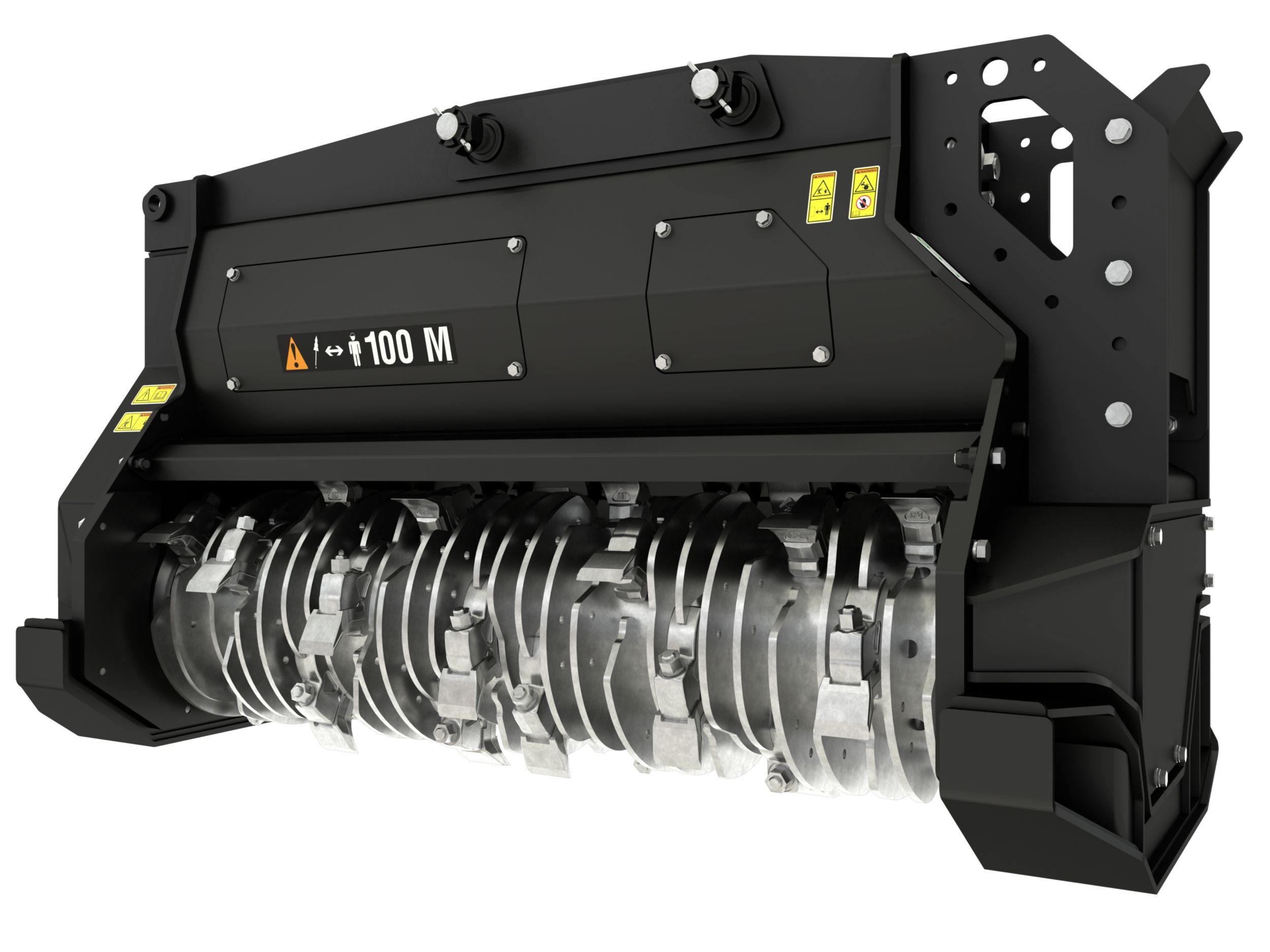

HM6015 Dedicated Bite Limiter Forestry Mulcher

Cat® forestry mulchers have industry-leading features to ensure you are getting the best productivity from a mulcher for tracked and wheeled excavators, all while keeping your work environment and equipment safe.

Reliable Performance

- Cut trees from 152 mm (6 in) up to 407 mm (16 in) in diameter.

- Two rotor types:

- Standard – rotor with teeth only

- Bite limiter – rotor with teeth separated by ribs to help prevent rotor stalling and creates finer shredded materials

- Variable torque hydraulic piston motor shifts between high speed, low torque and low speed, high torque to give you speed when you need it and power when it counts.

- Brackets allow the mulchers to be mounted to a variety of excavators within each size class.

- The staggered tooth design reduces stalling and jamming.

- Mulcher teeth options vary by application and preference on final material size:

- Standard: Most commonly used option. Fairly fine final product used where there is minimal rock present and durability is needed.

- Rock Crushing: Larger final product, but can work in applications where rocks are present.

- Bite Limiter: Very fine final product due to aggressive edge of the blade with the limiters and counter knives. Use where rocks are minimal and there are large amounts of standing timber.

- Hardened counter blades reduce finished material size and increase the rate of composting.

Easy Maintenance

- Access internal components quickly and easily with bolt-on service panels.

- Poly chain belt driven transmission eliminates slippage on startup, reducing maintenance costs.

- The motor is integrated into the frame to protect it from dust, damage, and impact from falling debris.

- Ensure service panel security with access bolts recessed into the panel, protecting them from debris.

- Get back to work faster with field-replaceable wear parts.

Prioritized Safety

- Hydraulic mulching door keeps the work environment and equipment safe by dispersing materials according to your application and surroundings.

- The mulching door operation is controlled by electric diverter valve or medium pressure hydraulic kits from the cab.

- Door closed – right-of-way clearing, near powerlines and pipelines, and roadside maintenance.

- Door open – vegetation management, jobsite clearing, forest wood fuel removal, and firebreaks.

- Flow control valve protects the motor from excessive flow.

- Ground-level primary grease points keep you safe while performing daily maintenance.

- Bolt-on, replaceable skids keep the mulcher from going into the ground or into materials expediting wear or causing damage.

Boost Efficiency and Productivity with Integrated Technologies

- Never waste time looking for your attachments again. Cat PL161 Attachment Locator is available on most attachments.

- Track your entire fleet of attachments and machines from one source. Attachments with asset tracking can be viewed within VisionLink® alongside Product Link™ subscribed equipment.

- Keep your assets secure. Attachments with an asset tracker send an alert if they leave an easy-to-setup site boundary.