D6

The Cat® Next Generation D6 Dozer, with more weight, horsepower, and technology than its predecessor, is the right choice from first cut to final grade. The proven Cat C9.3B engine with a fully automatic 4-speed transmission ensures there is power when needed. Common cabs and controls from the D5 to the D8 coupled with a broad range of technology simplifies operation across all bulldozers.

Powerful, Reliable, Durable

- Proven Cat® C9.3B engine eliminates Exhaust Gas Recirculation (EGR) system, updated fuel system, and simplification of electronic control modules (ECM) all contribute to a more reliable machine.

- Fully automatic 4-speed transmission continuously adjusts up or down for maximum efficiency and power to the ground without added operator input.

- Redesigned structure, with more weight and horsepower than D6T*, has configurations for you to build the machine for the work you do. Variable Power Angle Tilt (VPAT) tractors with improved range of motion for balanced, high-speed grading or robust Push Arm dozers for heavier applications, larger blades, and optional FirstCut™ cutting edges (SU blades only) for increased payload.

- Heavy Duty Extended Life undercarriage – HDXL with DuraLink™ – features Positive Pin Retention (PPR2) pins and link improvements for more seal life in high impact conditions.

- Cat Abrasion™ undercarriage is a low cost-per-hour solution for high abrasion and low impact jobsites. The design offers double the seal life and eliminates bushing turns, reducing your costs per hour compared to traditional undercarriage. Reduces link scalloping for smoother operation.

- Improved structures for HDXL and Cat Abrasion undercarriage enable changes from one to the other.

- Common sprocket mounting style as other dozers, with segments on the outside of final drive improve serviceability.

- Purpose-built Waste and Forestry/Heavy Duty arrangements.

Technology Made Simple

- Optional Assist features can reduce operator inputs up to 45%.* Cat Assist with Attachment Ready Option (ARO) features include:

- Attachment Ready Option (ARO) provides wiring and mounting provisions for dealer installation of Grade with 3D, Accugrade, UTS, or other grade control systems.

- Cat Grade with Slope Assist™ automatically maintains pre-established blade position without a GNSS/GPS signal — no additional hardware or software needed. For machines with 3D, operators can easily switch back and forth from full 3D automatics to Slope Assist.

- Steer Assist automates track and blade tilt steering. Helps reduce operator fatigue by automatically maintaining straight travel with light loads or heavy loads on flat ground and side slopes. Helps reduce steering inputs up to 75%. No GNSS/GPS required.

- Stable Blade works seamlessly with operator inputs to help produce a smoother surface when operating manually.

- Slope Indicate is included in the main machine display and shows side slope and uphill/downhill grades to help operators with slope work.

- Blade Load Monitor gives you real-time feedback on current load versus the optimal blade load based on your ground conditions. Actively monitors machine load and track slip to help you reach optimal pushing capacity.**

- Traction Control automatically reduces track slip to save you time, fuel and track wear.**

- AutoCarry™ automates blade lift to help you maintain consistent blade load and reduce track slip.**

- Application Profile lets you save machine settings based on application or operator preference. Utilize any of the default profiles defined by our expert operators or customize profiles for various jobs or multiple operators.

- Operator ID allows you to save custom touchscreen setup, machine settings, and to track individual operator productivity, safety and training opportunities via ProductLink™.

- Machine security – passcode helps prevent theft and unauthorized operation by requiring an operator to enter an ID to start the machine.

* Input reduction based on product testing of a D5 (17B) Next Generation Dozer with and without the use of Slope Assist in a side slope application. Inputs measured as number of times operator adjusts controls, collected and verified by electronic control module (ECM). Test conducted by Caterpillar at Washington, IL, in July 2022.

** Feature not operational indoors or in areas where GPS signal is not available.

Comfortable Workspace

- Redesigned, Next Generation cab offers commonality across all D5 through D8 dozers, including operator interface, sound reduction, more storage, and adjustable controls.

- Integrated rollover protective structure (ROPS) provides more glass surface area and better visibility.

- Cab options expanded to include Deluxe option. Levels of cab selection give you the ability to select your level of technology readiness and cab comforts and adjustments to suit your requirements.

- Operator adjustments available for 5th to 95th percentile operators to ensure comfort.

- Full-color 254 mm (10-inch) touchscreen display has an easy-to-use operator interface. Location of this display can be swapped with the Grade Control display. Viscous cab mounts reduce vibration for greater operator comfort.

- Wider air suspension seat has multiple adjustments for personalized comfort.

- Entire armrest adjusts forward and backward independent of the seat.

- Detented thumbwheel on the steering control allows easy speed setting changes.

- Ample storage spaces throughout the cab.

- Distributed cab heating/cooling circulates air more effectively around the operator and helps reduce window fogging/frosting.

Built-In Safety, Easy Maintenance

- Integrated ROPS and hood design, with alignment of the exhaust and precleaner, provide a better view of the front of the tractor and overall added visibility.

- Standard, integrated High Definition (HD) rearview camera in the primary display.

- The ladder at the back of the machine is standard for convenient access for fuel fill, window cleaning, and maintenance.

- Ground-level access to optional fast fuel fill, grab rails on both sides of cab roof, and tie offs provide added safety.

- Improved cab filtration for cleaner operator environment.

- Standard light package features 4 LED lights with the option to upgrade to 8- or 12-light packages and other optional, integrated LED warning lights.

- Bluetooth microphone gives you hands-free access to your mobile phone.

- Newer design reduces maintenance cost due to updated components, longer service intervals, fewer scheduled maintenance tasks.

- Grouped service points, modular components with easy access, and fewer filters save you routine maintenance time.

- Cab air filter replacement extended to 500 hours.

- Standard reversing fan extends the time between core clean-outs.

- 30-minute cab removal, for easy access to maintenance points, if needed.

- Modular, self-contained HVAC unit is easier to service.

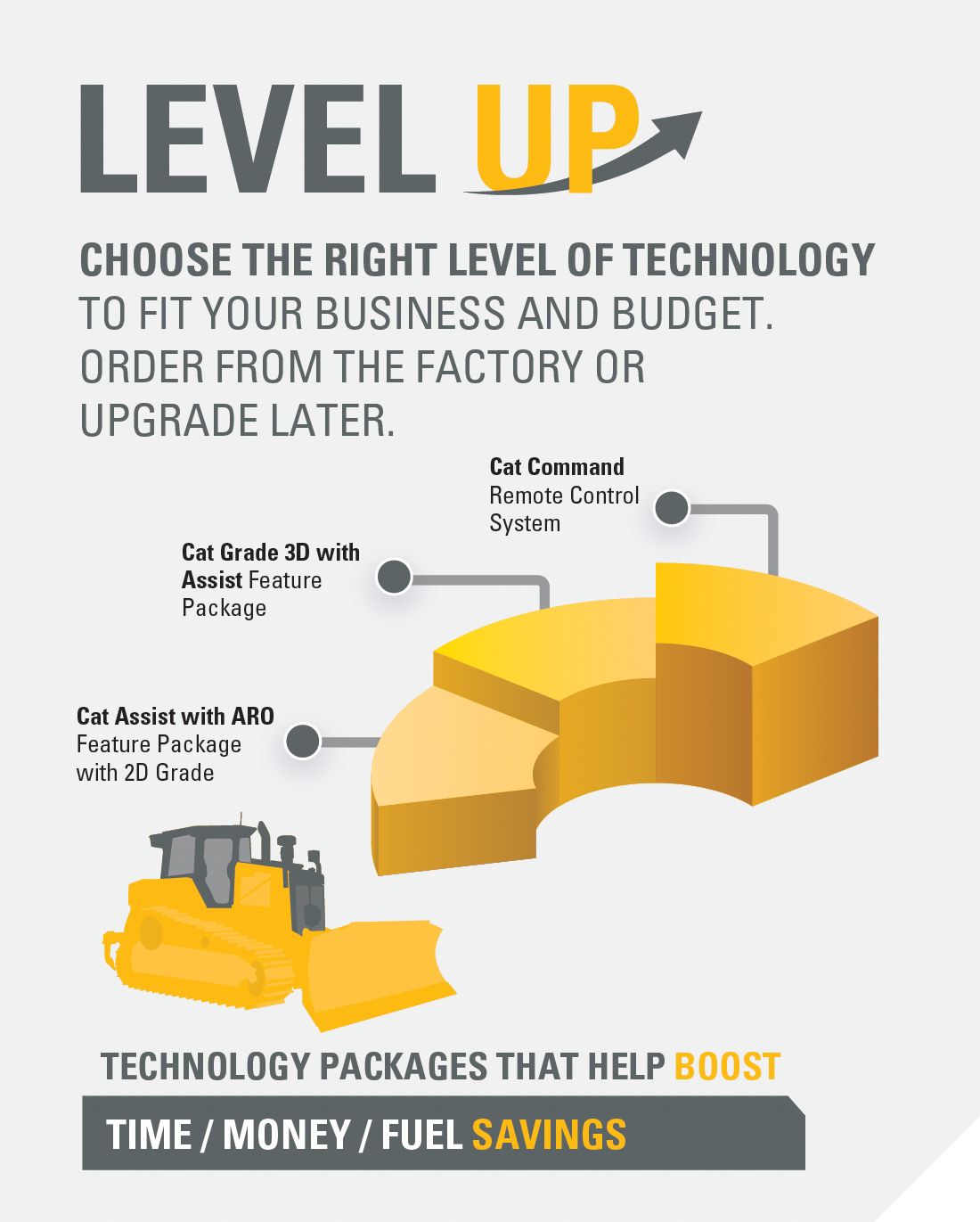

More Productivity With Cat® Technology

- Factory integrated Cat Grade with 3D uses GNSS/GPS to control the blade so you can get to design plan faster.

- Cat Grade with 3D has no masts – low profile antennas are integrated into the cab roof and GNSS/GPS receivers are mounted inside the cab for better protection.

- Automatically follow guidance lines from design plans with Steer Assist 3D. Stay on curb lines, centerlines, bottom of slope, etc., without operator effort. Track steering is used under light loads and blade tilt steering may be added under heavy loads.

- Grade operator interface is intuitive and easier to use: 10-inch (254 mm) touchscreen, Android OS platform, operates like a smart phone.

- All Cat Grade systems are compatible with radios and base stations from Trimble, Topcon, and Leica. Already invested in a grade infrastructure? The cab is Third Party Grade Control Ready, equipped with CAN interface, harness pass throughs and mounting features to make it easier to install the grade control system of your choice.

Remote Control Ready

- Cab is Remote Control Ready from the factory with external connector for dealer installation of the Cat Command system.

- Cat Command remote control technology provides full dozer maneuverability from a safe distance when working in hazardous environments.

- Command offers the choice of line-of-sight consoles or long-distance operator stations (non-line-of-sight).

- Take advantage of the dozer's Grade and Assist features while out of the cab using the Command Station or Console.*

Configuration Options

- Specialized guarding and seals throughout the machine help protect major components from impact and airborne debris.

- Waste cab has impact-resistant polycarbonate doors, eliminating the need for door screens.

- Larger capacity landfill blades, front and rear striker bars, and center-hole track shoes optimize the machine for waste handling applications.

- Multi-layer final drive guards, including a labyrinth-style guard with 90-degree turns, help keep dirt and debris away from the Duo-Cone™ seal to protect final drive oil.

- Tilt cylinder with rotating bushing type design help wrapping materials to roll off hoses.

- Heavy-duty, hinged radiator guard protects radiator and fan from penetration by material coming straight in or from under the blade.

- Cooling system designed for high debris environments, with automatic reversing fan and swing-out cleanout access.

- Powered precleaner is integrated and increases the cab filter change interval to 1,000 hours.

- Laminated thermal shields and insulated Clean Emissions Module.

- Bottom guard, chassis and tilt cylinder guards, and guarding over the fuel tank and battery box for extra protection from debris.

Heavy Duty/Forestry

- Forestry cab with impact-resistant, polycarbonate doors for added safeguard without the use of door screens. Side and rear screens can help further protect the operator and machine from debris. Hinged screens provide easy access to windows for cleaning and maintenance.

- Closed sweeps provide more protection for the operator and machine with an enclosed canopy over the cab to protect the top of the machine while allowing upward visibility. Optional open sweeps can be used for applications where a canopy is not preferred.

- High debris seals offer additional protection around fenders, fuel tank, radiator guard and rear hood support. Provides a seal across the top, rear of the case to prevent debris entry.

- Single plane cooling system with automatic reversing fan aids cleanout. High debris engine air filtration system extends filter life.

- Heavy duty bottom guards and fuel tank guard help shield major machine components. Sealed bottom guards available on push arm machines.

- Heavy Duty Extended Life (HDXL) undercarriage. Track bushings can be turned and re-sealed mid-life. Press-fit bushings and PPR2 pin retention are particularly well suited for impact applications like forestry.

- Premium light package with 12 LED lights with light guards provide 360-degree light coverage.