Cat Payload for Next Generation Wheel Loaders

Cat® Payload technologies provide on-the-go weighing to help operators hit exact targets, everytime and avoid overloading, underloading or misloading materials.

Integrated Technology

- Payload is standard on many new next generation wheel loaders.

- Integrated technologies provide operators a simple to use tool for precise loading.

- Built-in Assist features allow for automation of some operations for even more efficiency and productivity.

- Payload can upgraded to Advanced Payload for additional capabilities and features.

- NOTE: Payload technologies are not legal for trade.

Deliver Results

- Reduce Costs - Save on time, labor, and fuel costs.

- Improve Accuracy - Precise payload targets eliminates over and under loading.

- Increase Operator Efficiency - Experienced operators work more accurately than ever, while new operators can get up to speed more quickly.

- Enhance Safety - Prevent truck overloading, which creates heavier and more unstable loads, reducing braking performance and putting the driver at greater risk of tipping.

How It Works

- The Cat Payload system calculates material weight on-the-go by using data from sensors that measure bucket position and hydraulic pressure.

- Automatic weighing provides estimated weights at low lifts (below weigh range) and scaled weights with the boom raised (through the weigh range).

- Easily tip-off excess material on the last pass with real-time weight estimates for precise loading - eliminate under / over loading.

- Bucket payloads are transferred to the truck cumulative payload weight as soon as an estimated weight is calculated. The bucket load is latched to the truck once the bucket is fully dumped.

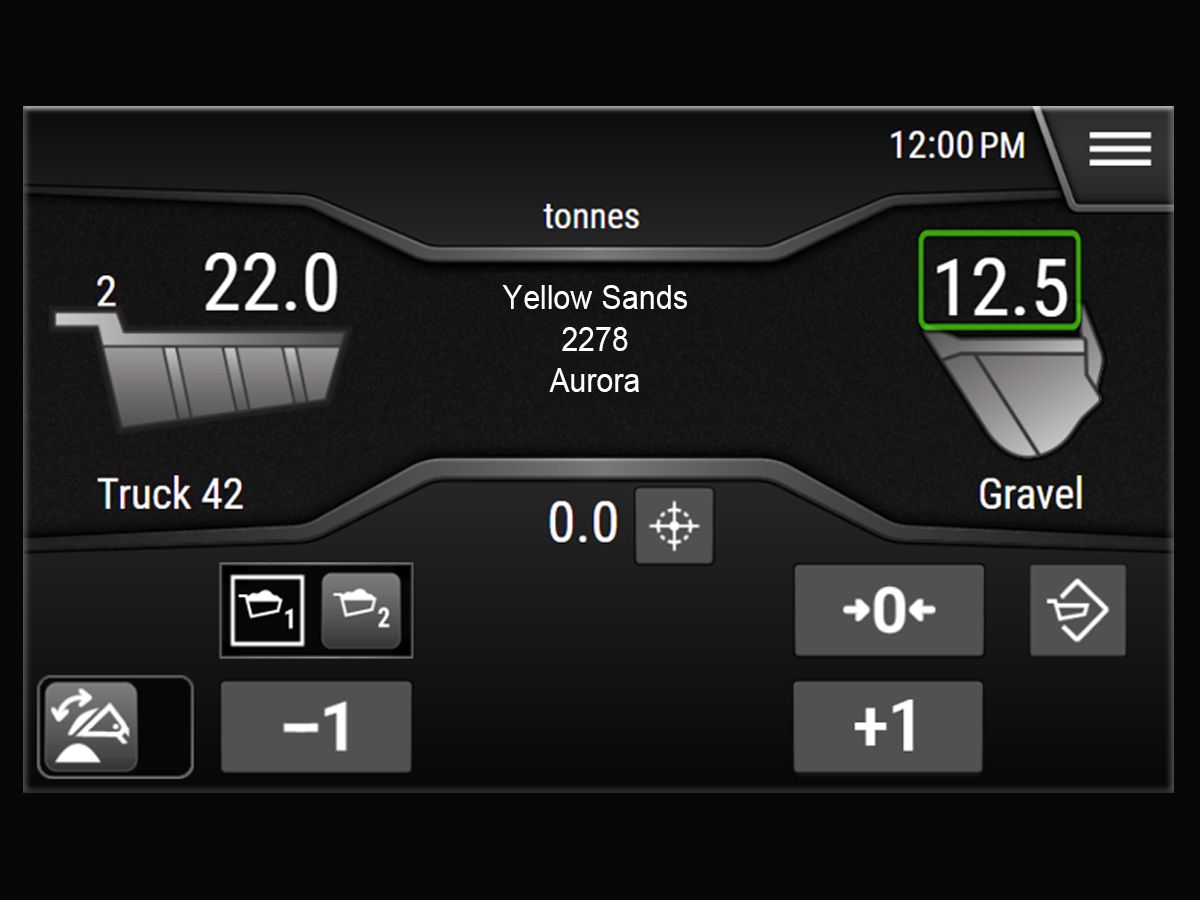

- View bucket payload and truck cumulative payload weight effortlessly from the touchscreen monitor.

- Receive payload overload alerts when bucket loads exceed machine payload limits.

Operator Assist Features

- Assist features on next generation wheel loaders add semi-autonomous functionality to boost operator efficiency.

- Auto Set Tires - Aids operators with proper digging technique by detecting pile engagement to reduce tire slip for longer tire life.

- Autodig - Performs a full dig cycle for the operator. Upon detecting a dig condition Autodig will command lift and tilt functions to fill the bucket, then raises to kickout height.

- Programmable Kickouts - Automates repetitive tilt, lower and lift functions to reduce operator fatigue, resulting in higher efficiency for greater productivity.

- Machine Speed Limit - Allows operators to control the machines top speed which helps save fuel by limiting runout speed in load and carry applications.

- Tip-Off Assist - An Advanced Payload feature that removes the need for the operator to manually dump (meter load) to target. When the operator initiates the final pass weighing process and activates Tip-Off Assist, the loader will automatically tip-off to target weight.

Advanced Payload Upgrade

- Advanced Payload is a system upgrade that offers expanded features and capabilities, including:

- Advanced list options provide additional information to a load cycle - truck ID, material type, and up to four customizable lists.

- Tip-off Assist adds automation to the final bucket process.

- Multitask mode tracks two loading processes simultaneously.

- Dispatch for Loading integrates the loader into the scale house process - a subscription and compatible scale house software required.

- Advanced Payload can be installed at the factory for all new next generation wheel loaders or added as a dealer installed upgrade kit.

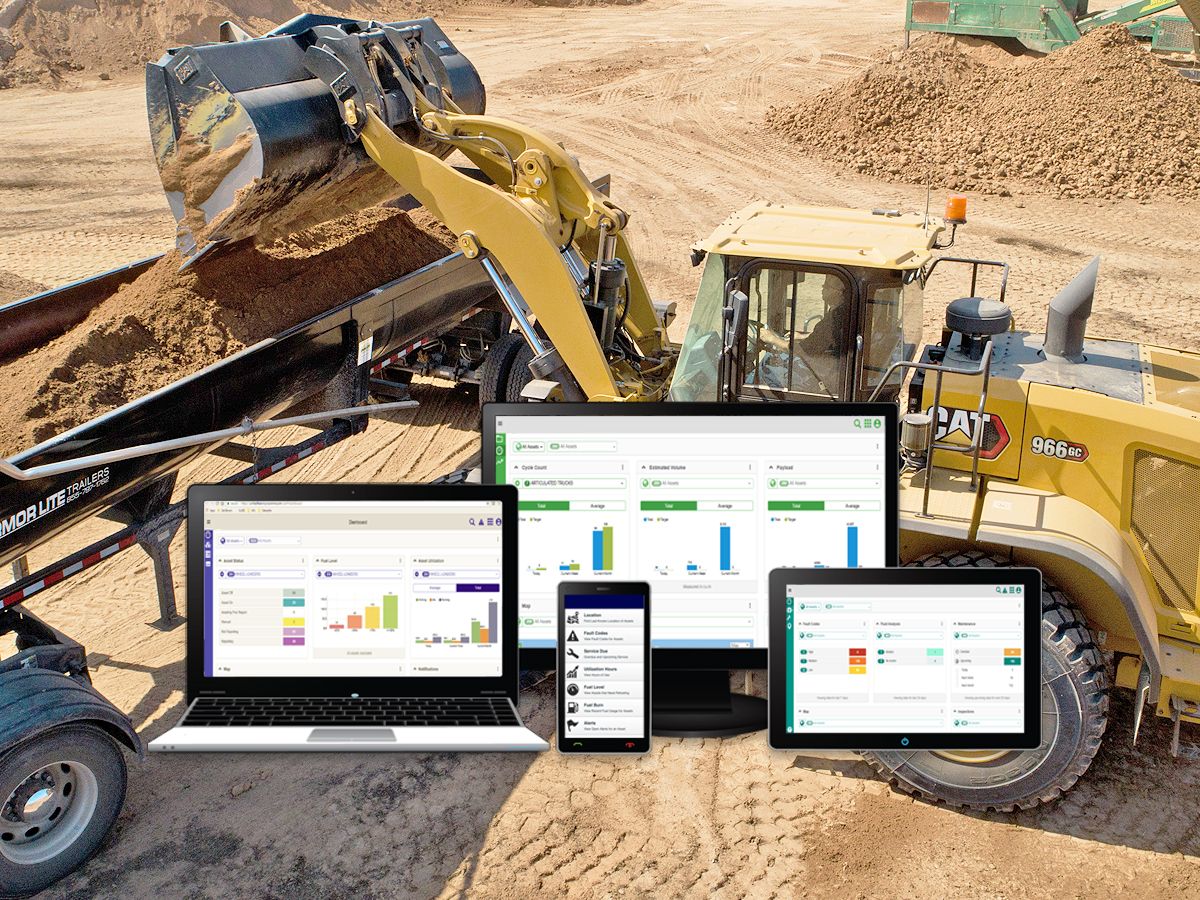

Monitor Performance

- Operators can track daily production from the cab with quick access to truck weights, load and cycle counts, material movement, and daily totals.

- Print truck payload tickets - Optional printer required.

- Managers can view payload details and key performance indicators online to help manage the business - requires a VisionLink® and VisionLink® Productivity subscription.